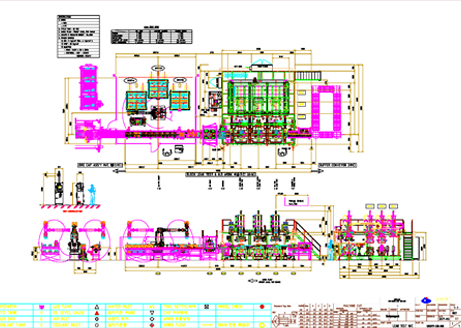

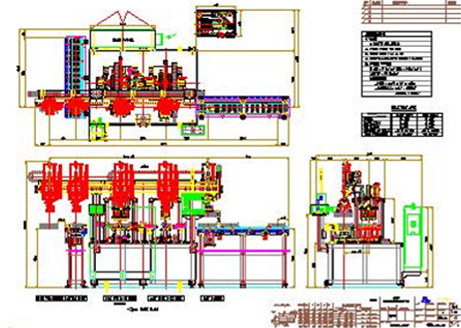

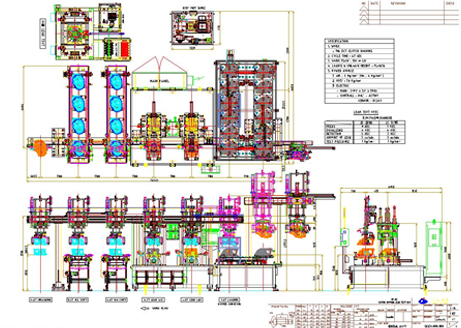

CYL BLOCK LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

OIL LINE LEAK TEST |

| 3 - ST |

W/J LEAK TEST |

| 4 - ST |

CRANK ROOM LEAK TEST |

| 5 - ST |

NG CONVEYOR |

| 6 - ST |

AIR BLOW |

| 7- ST |

UNLOAD’G |

SPECIFICATION

| Type |

Transfer Type |

| Work Transfer |

Pallet Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

39 sec/ea |

| LEAK TEST SPEC |

|

OIL LINE |

WATER JACKET |

CRANK ROOM |

| PRESS |

7 SEC |

7 SEC |

7 SEC |

| EQUALIZING |

5 SEC |

5 SEC |

5 SEC |

| DETECTION |

3 SEC |

5 SEC |

4 SEC |

| AMOUNT OF LEAK |

7.5 cc/min |

15 cc/min |

26 cc/min |

| TEST PRESSURE |

4 Kgf/cm² |

3 Kgf/cm² |

0.5 Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

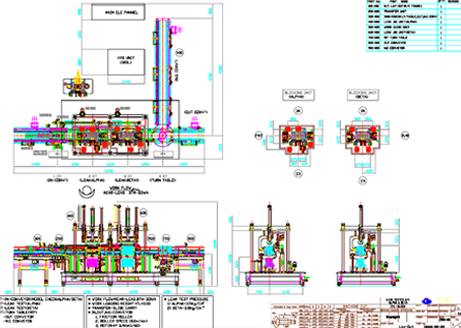

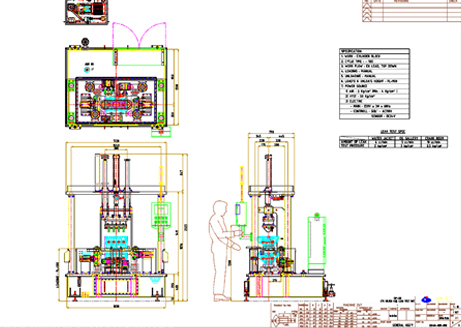

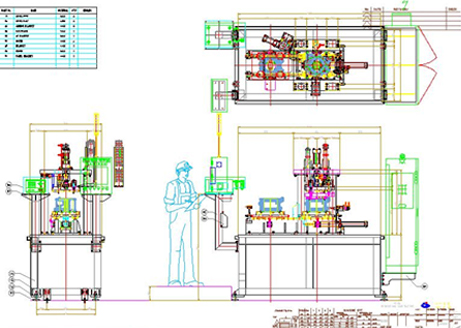

CYL BLOCK LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

MODEL CHECK |

| 3 - ST |

ALPHA LEAK TEST |

| 4 - ST |

BETA LEAK TEST |

| 5 - ST |

TURN TABLE |

| 6 - ST |

NG CONVEYOR |

| 7- ST |

UNLOAD’G |

SPECIFICATION

| Type |

Transfer Type |

| Work Transfer |

Pallet Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

50 sec/ea |

| LEAK TEST SPEC |

|

ALPHA |

BETA |

| TEST PRESSURE |

3.5 Kgf/cm² |

3.5 Kgf/cm² |

|

|

|

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

|

| Air |

27,000 L/min |

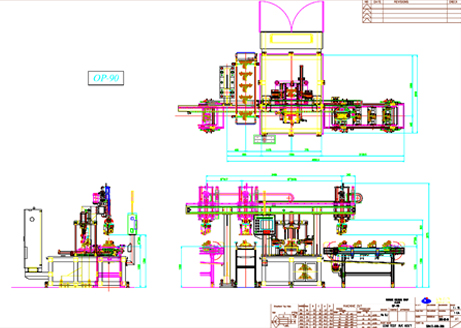

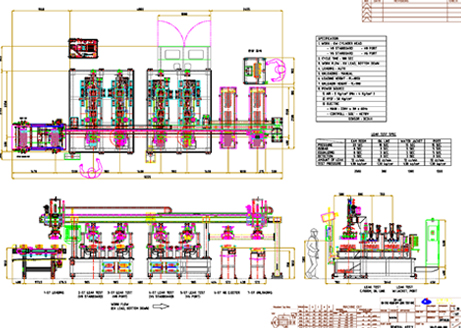

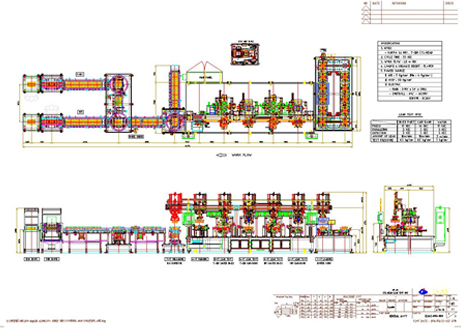

TURBINE HSG 180HP LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

MODEL CHECK |

| 3 - ST |

LEAK TEST |

| 4 - ST |

NG CONVEYOR |

| 5 - ST |

UNLOAD’G |

SPECIFICATION

| Type |

Full Auto Type |

| Work Transfer |

Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

83 sec/ea |

| LEAK TEST SPEC |

TEST PRESSURE |

10 mL/min |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of Material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置

|

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| Water |

Dirty Tank. 2500L Clean Tank. 2000L |

| Air |

27,000 L/min |

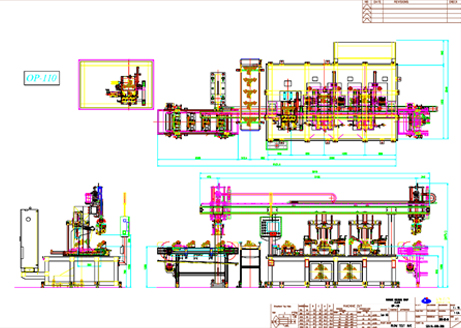

TURBINE HSG 180HP FLOW TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

V/V SEAT LEAK TEST |

| 3 - ST |

V/V SEAT LEAK TEST |

| 4 - ST |

QR CODE MARK’G & READ’G |

| 5 - ST |

NG CONVEYOR |

| 6 -ST |

UNLOADING |

SPECIFICATION

| Type |

Full Auto Type |

| Work Transfer |

Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

83 sec/ea |

| LEAK TEST SPEC |

V/V SEAT |

7 L/min |

| V/V STEM |

29L/min |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| Water |

Dirty Tank. 2500L Clean Tank. 2000L |

| Air |

27,000 L/min |

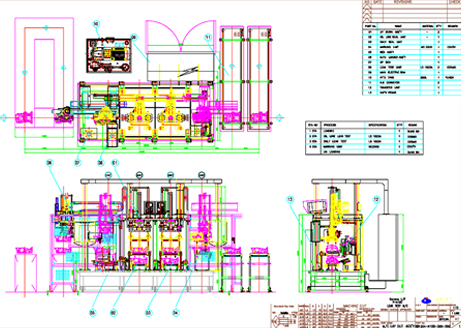

D16DTF LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

IN-EX PORT LEAK TESK |

| 3 - ST |

CAM ROOM |

| 4 - ST |

N.G CONVEYOR |

| 5 - ST |

UNLOADING |

SPECIFICATION

| Type |

Full Auto Type |

| Work Transfer |

Roller Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

160 sec/ea |

| LEAK TEST SPEC |

|

IN-EX PORT |

CAM ROOM |

| PRESS |

10 SEC |

10 SEC |

| EQUALIZING |

4 SEC |

4 SEC |

| DETECTION |

3 SEC |

5 SEC |

| AMOUNT OF LEAK |

-10 ~ 5 cc/min |

-10 ~ 5 cc/min |

| TEST PRESSURE |

0.5 Kgf/cm² |

0.5 Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

CYL BLOCK HANDY LEAK TESTER

SPECIFICATION

| Type |

- |

| Work Transfer |

- |

| Load’g & Unload’g |

- |

| Cycle Time |

-sec/ea |

| LEAK TEST SPEC |

|

WATER JACKET |

OIL GALLERY |

CRANK ROOM |

| AMOUNT OF LEAK |

6 cc/min |

5 cc/min |

10 cc/min |

| TEST PRESSURE |

2 Kgf/cm² |

3 Kgf/cm² |

0.5 Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

- |

| Safety |

- |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

GW LEAK TESTER

CONVEYOR + PALLET+ROBOT

GW CYL-HEAD 6 & 8 CYL

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

LASER MARK’G |

| 3 - ST |

V8 LEAK TESK |

| 4 - ST |

V6 LEAK TEST |

| 5 - ST |

NG CONVEYOR |

| 6 -ST |

NG CONVEYOR |

SPECIFICATION

| Type |

Full Auto Type |

| Work Transfer |

Belt Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

180 sec/ea |

| LEAK TEST SPEC |

|

CAM ROOM |

OIL LINE |

W/JACKET |

PORT |

| PRESS |

20 SEC |

10 SEC |

15 SEC |

15 SEC |

| ISOBAR |

8 SEC |

3 SEC |

5 SEC |

5 SEC |

| EQUALIZING |

8 SEC |

3 SEC |

5 SEC |

5 SEC |

| DETECTION |

5 SEC |

3 SEC |

3 SEC |

3 SEC |

| AMOUNT OF LEAK |

12 cc/min |

12 cc/min |

12 cc/min |

12 cc/min |

| TEST PRESSURE |

1.38Kgf/cm² |

1.38Kgf/cm² |

1.38Kgf/cm² |

1.38Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

GAMMA LADDER FRAME LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

OIL LINE LEAK TEST |

| 3 - ST |

ONLY LEAK TEST |

| 4 - ST |

MARK’G |

| 5 - ST |

UNLOAD’G |

SPECIFICATION

| Type |

Transfer |

| Work Transfer |

Roller Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

40 sec/ea |

| LEAK TEST SPEC |

|

OIL LINE |

|

| PRESS |

9 SEC |

|

| EQUALIZING |

8 SEC |

|

| DETECTION |

8 SEC |

|

| AMOUNT OF LEAK |

5 cc/min |

|

| TEST PRESSURE |

5 Kgf/cm² |

|

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

DCT CLUTCH HOUSING LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

BUFFER CONVEYOR |

| 3 - ST |

LEAK TEST (2D) |

| 4 - ST |

LEAK TEST (2C) |

| 5 - ST |

NG CONVEYOR |

| 6- ST |

UNLOAD’G |

SPECIFICATION

| Type |

Transfer |

| Work Transfer |

Slide + Belt Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

47 sec/ea |

| LEAK TEST SPEC |

|

2D |

2C |

| PRESS |

9 SEC |

9 SEC |

| EQUALIZING |

4 SEC |

4 SEC |

| DETECTION |

3 SEC |

3 SEC |

| AMOUNT OF LEAK |

3 cc/min |

3 cc/min |

| TEST PRESSURE |

1 Kgf/cm² |

1 Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

DU MOTOR HSG LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

LEAK TEST |

| 3 - ST |

NG EJECTOR |

| 4 - ST |

UNLOAD’G |

SPECIFICATION

| Type |

Transfer, Servo Motor |

| Work Transfer |

Shuttle + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

200 sec/ea |

| LEAK TEST SPEC |

|

WATER |

All of parts |

| TEST TIME |

10 sec |

10 sec |

| TEST PRESSURE |

2 Kgf/cm² |

2 Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |

KAPPA CYL HEAD LEAK TESTER

| STN |

NAME |

| 1 - ST |

LOAD’G |

| 2 - ST |

BUFFER CONVEYOR |

| 3 - ST |

LEAK TEST (MPI CAM-ROOM) |

| 4 - ST |

LEAK TEST (MPI WATER IN-EX) |

| 5 - ST |

LEAK TEST (T-GDI CAM-ROOM) |

| 6 - ST |

LEAK TEST (T-GDI WATER IN-EX) |

| 7 - ST |

MARKING |

| 8 - ST |

NG CONVEYOR |

| 9 - ST |

UNLOAD’G |

SPECIFICATION

| Type |

Transfer |

| Work Transfer |

Pallet Conveyor + Auto Loader |

| Load’g & Unload’g |

Auto Loader |

| Cycle Time |

55sec/ea |

| LEAK TEST SPEC |

|

IN-EX PORT |

CAM ROOM |

WATER |

| PRESS |

17 SEC |

14 SEC |

17 SEC |

| EQUALIZING |

3 SEC |

3 SEC |

3 SEC |

| DETECTION |

3 SEC |

3 SEC |

3 SEC |

| AMOUNT OF LEAK |

10 cc/min |

10 cc/min |

5 cc/min |

| TEST PRESSURE |

0.5 Kgf/cm² |

0.5 Kgf/cm² |

3 Kgf/cm² |

| MEASURING UNIT |

COSMO or Maker specification |

| Compensation of material temperature |

前工程 WAHING 設備がある時素材溫度が上がって

LEAK DATA散布がひどくなります。

入口にMIN 30分以上のSTOCKER CONVEYOR 設置 |

| Safety |

HEAD手作業時落下防止 STOPPER 設置 |

| Utility |

Voltage |

220/380/415/440 3P 60Hz |

| HYD |

50 Kgf/cm² |

| Air |

27,000 L/min |